We recognise the value of water as an increasingly global concern and the impact of its use on our business activities. Therefore, we are coordinating our operations with steps to reduce freshwater consumption by minimising the water footprint and maximising the recycling and reusing of water.

Most of our water usage is for office and housekeeping facilities, or in HVAC systems to support cooling equipment. Even though our operations are not as water-intensive as those of manufacturing industries, we consider it to be a material aspect and have undertaken steps for water conservation across our facilities. Since many of our international operations facilities are on a lease, we consider water as a material issue for our Indian operations only.

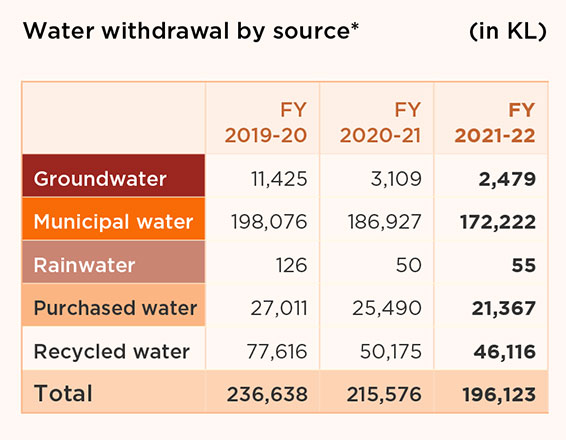

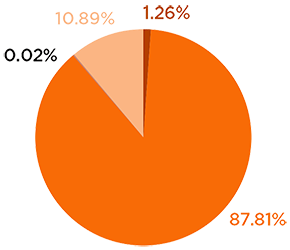

During FY 2021-22, we drew nearly 1,96,122 KL of water, of which 88% was from municipal facilities, 11% from third-party tankers and bottled water, and the remaining 1% through rainwater harvesting and groundwater extraction. We reduced 9% of our consumption due to stringent monitoring of water consumption, arresting leakages, and creating awareness among the contract workforce. Water recycling accounts for 23.5% of the total water withdrawal. In smaller sites where recycling and treating installation are not feasible, the wastewater is discharged into the municipal drainage system after appropriate approvals from the authorities.

Water risk management

We conduct a Water Risk Assessment exercise regularly, which helps us to improve our internal processes, and facilitates the identification of inefficiencies in water use or distribution system. Our Water Risk Assessment exercise for all major facilities was revisited during FY 2020-21, wherein sites falling under critical results were asked to set up objectives and targets, along with plans to conserve and improve water recycling in their region.

9%

Reduction in water consumption as compared to FY 2021-22

Water management strategy

Our operations and facilities align with the ‘3R’ resource management strategies: reduce, reuse and recycle, allowing us to mitigate our water footprint throughout our operations by optimising water consumption, and increasing our recycling capacity. Some of our actions include:

Consumption, monitoring and awareness

Resource allocation

Minimising waste

196,123 KL

Total water withdrawal by

source in FY 2021-22

* From FY 2021-22, we have started accounting for only Tata Communications consumption. Water consumption in shared premises is accounted on the basis of charge backs or amount paid by the entities using the Company’s water supply. Data figures for FY 2019-20 and FY 2020-21 have also been updated accordingly.

Being water-savvy

![]() Reduce

Reduce

Technical intervention plays an important role in optimising our water usage. To reduce water consumption, we have installed sensor-based faucets in all toilets and cafeterias in major locations. To further account for our consumption at each activity level, we are automating and increasing water meter installations at all our facilities. Following the success of the pilot IoT water monitoring project at the Dighi campus, Pune (one of our largest campuses), we are installing IoT meters in the rest of our major facilities. The project will be implemented in FY 2022-23, and is expected to strengthen the monitoring of water loss, helping in substantial water savings in the facilities.

![]() Reuse

Reuse

We utilised nearly 46,116 KL volume of wastewater treated at our sewage treatment plant for landscaping and gardening purposes. This minimised our freshwater withdrawal and resulted in cost savings. To maximise the rainwater harvesting capacity, we have conducted feasibility studies at four of our sites. Based on the results of the studies, we will increase our rainwater harvesting capability beginning FY 2022-23. The total rainwater harvesting capacity is expected to be 13,439 KL, once the project has been implemented at the identified sites. Furthermore, to give back to the environment, we are also developing ground water recharge infrastructure with the recharge potential of 53,520 KL per annum.

![]() Recycle

Recycle

Water recycling and efficiency are critical aspects in a water-stressed country like India. Therefore, we have installed wastewater treatment plants at most of our facilities, where the wastewater generated is treated through Sewage Treatment Plants (STP) and recycled for other domestic applications, such as gardening and water sprinkling, etc. For some sites, treated water is discharged to the municipal drains after complying with all regulatory requirements.

46,116 KL

Water recycled back into

gainful use in FY 2021-22

Upgradation of STP Plant

We encountered several issues with our old STP plant in GK-1, New Delhi such as, part malfunctioning, excess sludge, degradation of sewage treatment capacity, and water seepage from the roof due to the old structure. Therefore, the main objective of this project was to maintain the STP operations with no impact on the environment. A detailed audit was conducted for STP operations by an expert agency. Based on its suggestions, upgradation was planned to meet the basic operations and maintenance requirements. This upgradation provided three key benefits:

Efficient waste management

Effective waste management is an integral part of our sustainability strategy. We focus primarily on waste minimisation to reduce the overall waste footprint. We also use efficient and environmentally friendly disposal methods to minimise the impact of waste generated and reduce the amount of waste that is landfilled.

As a service-oriented Company, we usually do not process or generate waste. We rely on our suppliers to provide the products and services we need to run our business. Therefore, we have minimal control over it. We are committed to reducing waste and expanding our business’s recycling capacity. Our products are intangible, therefore, waste generation and disposal on the customer side, remain a negligible issue.

Waste footprint

We categorise our waste as non-hazardous and hazardous:

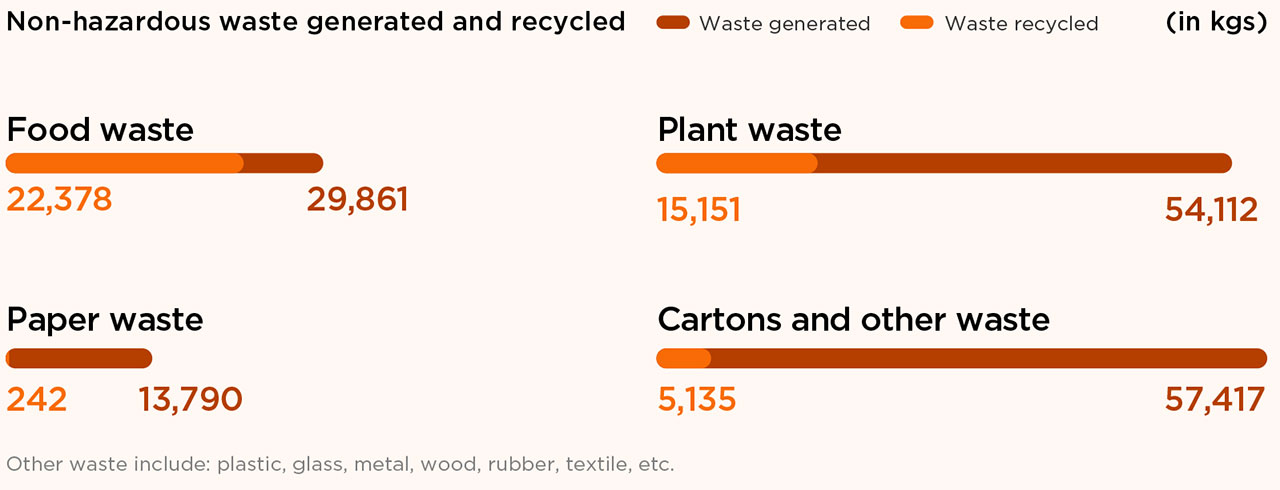

Non-hazardous waste

The non-hazardous waste generated at our facilities is municipal solid waste, which is collected and segregated into various categories, such as paper, food, plant thrush, plastic, metal, cartons, and more. We dispose of the non-hazardous waste generated at our facilities through various channels, such as recyclers and municipal corporations. We have installed Organic Waste Convertors (OWCs) in all our major facilities to convert the food waste generated from our cafeterias into manure, and to reuse it within the facilities. This has helped us in composting ~22,378 kilograms of food waste.

22,378 kgs

Food waste composting in the house

To reduce our waste, we have implemented several initiatives, such as the replacement of plastic water bottles in our meeting rooms with glass bottles, and switching to reusable ceramic or acrylic mugs in our cafeteria. Our Corporate Services team organises regular ‘awareness sessions’ for waste handlers within the facility, to ensure proper waste management and minimise the risk of contamination and spill.

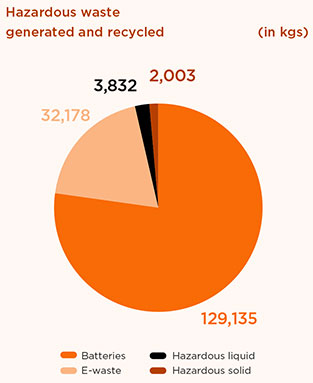

Hazardous waste

In addition to the non-hazardous waste generated from day-to-day operations, hazardous waste, such as used oil, oil filters, and oil-soaked cotton from diesel generator sets, used batteries from energy utilities and e-waste, are generated from equipment, such as desktops, laptops, and other office and electronic equipment. We ensure adequate storage with secondary containments during the collection and handling of such hazardous waste, and ensure proper training of the waste handlers. The waste is disposed of by authorised recyclers and processors through Metal Scrap Trade Corporation Limited, and it is ensured that all regulatory requirements of waste management rules of relevant regions or countries are followed.

We implemented a waste management project focussed on developing compost from our plant trash at Dighi campus, Pune. The main objectives of this project were to:

We collected more than 125 kilograms of trash/month from the campus and decomposed it into our waste pits. This project resulted in the processing of 6,929 kilograms of plant waste within a year.

We focussed on improving our current waste management process at our Dighi Campus in Pune. We created compost pits to recycle plant waste, started waste segregation as hazardous and non-hazardous waste, segregated biomedical waste as per government regulations, and displayed boards at food counters, to create awareness. We also provided training to housekeeping, pantry boys, gardeners and cafeteria staff on a regular basis to create awareness and enhance their skills in waste management. The process is smoothened, and we are now looking towards all the waste generated to be reused and recycled within the campus, and aiming for zero waste disposal.